|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MACRO

MACHINE INC. Engineered

Manufacturing Systems

|

HOME

CONTACTS

ABOUT US

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

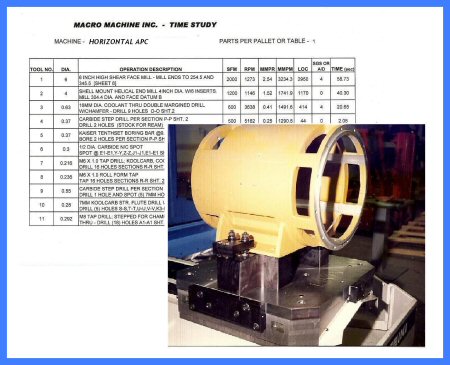

PROCESS/TIME STUDIES

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IN ORDER TO MOVE FORWARD WITH

A PROJECT, IT IS NECESSARY TO DEVELOP THE PROCESS.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS DEVELOPMENT

-

Study the Part Prints

-

Identify Location Point Requirements

-

Consider the Part for Number of Operations Required

-

Ask......Will This Part Fit Best on a Lathe,

VMC, or HMC or a Combination of Machines

-

Always Strive to Complete the Machining in One

Operation if Possible

-

If the Machine is a VMC Should it Be an APC

Type

-

If the Work Holding Will Be Complex Make Rough

Layouts to Assure Capability

-

Establish the Number Of Parts Machined in One

Clamping (Parts On)

-

Based on the Above, "Write" the Process

and Establish the Cut Tooling Required for Each Step

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TIME STUDY

With the Process Developed, and the Tools Selected,

It is Possible to Create a Time Study. There is software Available

for This. However, We Prefer Not to Use It. We Feel That There is

No Substitute For Practical Experience and Software Can Not Make Intuitive

Decisions.

Cutting Tool Manufacturers Do Provide Considerable

Information Regarding Speeds and Feeds. You Will Find That a Large

Range in the Values Are Given. Some People Use the Mean of These Values.

We Prefer to Look at Each Case Individually and Tend to be More Conservative.

The Non-Cut Time (Rapids, ATC, APC, Accel/Decel...)

Will Vary Greatly From Machine to Machine. We Use the Builder's Information

Coupled With Experience and Testing For These Values.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOW DO WE GET STARTED?

GOOD INFORMATION WILL ENABLE US TO

MORE PRECISELY ADDRESS YOUR EXPECTATIONS. PLEASE CONSIDER THE FOLLOWING:

-

Part Prints - Can Part Prints Be Provided as

Electronic Files? AutoCad, VersaCad, or SolidWorks is Preferred.

PDF is Okay But Not Our First Choice. Faxed Copies of Reductions

of Large Drawings Are Very Difficult to Read. If the Part Is a Casting

or Forging, Please Provide This Drawing As Well.

-

Material Specification - If the Material Spec

Refers to an Internal Document or Standard, Please Provide This

Information.

-

Production Time Available - How Many Shifts

Are Worked and What is the Efficiency Standard?

-

Is This Part Currently Being Produced? If So,

Please Provide Any Pertinent Information Available

-

Is There a Production Rate (Cycle Time Per Part)

Target?

-

Are There Any Internal Specs Regarding Tolerances

or Finishes?

-

Are Sample Parts Available? Castings, Forgings,

Machined Parts.....This is Very Helpful

|

|

|

|

WITH GOOD INFORMATION, WE CAN PROVIDE THE DATA YOU

NEED TO MAKE THE BEST DECISIONS FOR YOUR COMPANY.

E-MAIL, CALL OR WRITE US AND LETS GET STARTED!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|