MACRO MACHINE INC. Engineered Manufacturing Systems |

|

||||||||||||

|

|

|

|

|

|

|

|||||||

SPECIAL MACHINERY DESIGNED & BUILT BY MACRO MACHINE INC. |

|||||||||||||

In Addition, Macro also does CNC Machine Retro-fitting and Reconditioning:Click the following link to see some examples | RETRO-FITS |

|||||||||||||

|

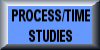

DOUBLE END LINE BORING MACHINEMACHINES BEARING BORES ON BOTH ENDS OF PRINT ROLL

|

||||||||||||

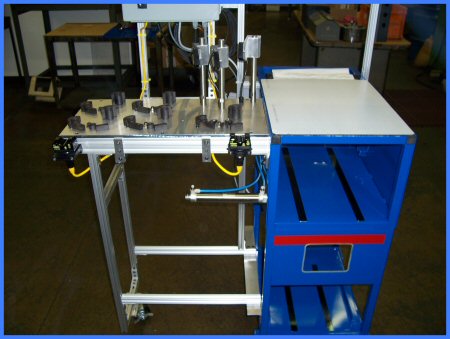

SIX STATION HYDRAULIC PRESSPRESSES SIX BEARINGS IN ONE CYCLE

|

|

||||||||||||

|

PART CHECKER FOR THREAD PRESENCELASERS SENSE THAT THREE HOLES ARE TAPPED

|

||||||||||||

BEARING BALL PRESSSEPARATES AND PRESSES FOUR BALLS AT ONCE

|

|

||||||||||||

|

SORTERSSORTS WASHERS FOR CLIPS AND NULL PUNCHES

|

||||||||||||

MAGAZINE FEEDERSEPARATES BAR STOCK FOR ROBOT PICK UP

|

|

||||||||||||